Printing technologies Thermal Transfer vs. Direct Thermal. What is the difference and what does it mean?

You have probably come across the term "Direct Thermal" or "Thermal Transfer". Mostly these terms appear in the parameters of products such as label printers, label maker ribbons, self-adhesive labels, ink ribbons or label makers. But do you know what they really mean? Don't you? In this article, you'll find all the important information you need to know on this topic.

Label printers use thermal printing, which means they don't need any ink cartridges or toners compared to traditional desktop printers. This method excels in situations where you need to print quickly and easily. Well, you probably already guessed that this printing method will be divided into the aforementioned thermal transfer and direct thermal technologies.

Thermal printing is used for printing:

- Self-adhesive labels and paper labels (DT i TT)

- Receipts and travel documents (DT)

- Plastic Cards (TT)

- Wristbands (TT)

- Shrink tubes (TT)

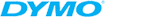

Direct thermal printing (DT)

Inside the printer is the print head and its base is the heating elements. Underneath, a special thermal paper passes through it, which is coated with a special chemical heat-sensitive layer. This changes colour from white to black when heated with the thermal head.

Direct thermal label printers are amazingly quiet and fast. On the other hand, they have the disadvantage that they can only print in black and white and have a relatively low resolution - up to 300 dpi (dots per inch), so you can print photos with them, but never with the quality of an inkjet or laser printer.

Unfortunately, thermal paper is also sometimes a disadvantage, as it fades quickly after contact with ambient heat, any heating element, or the sun light (UV). Direct thermal printing is therefore not suitable for printing documents of a permanent nature, such as sales contracts, employment contracts or invoices. It is also not recommended for labels on products that are exposed to outdoor conditions (mainly sunlight).

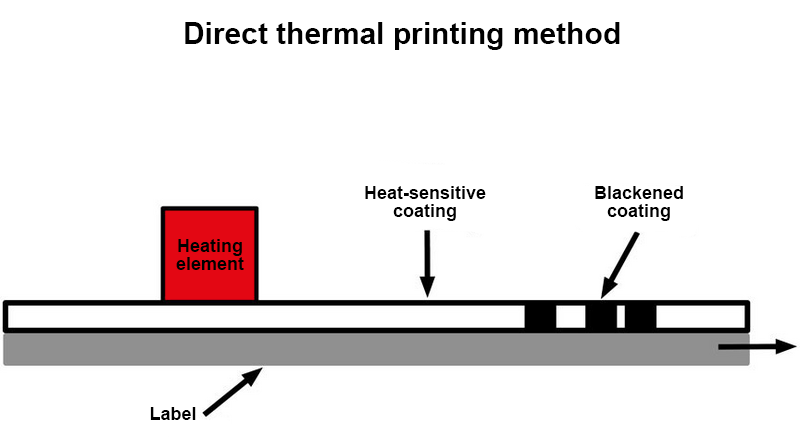

Thermal transfer printing (Thermal Transfer = TT)

Thermal transfer printing, also known as TT - Thermal Transfer, is a more advanced method compared to Direct Thermal technology. The basis of thermal transfer printers are color ribbons made of polyester infused with dye. The dye from the ribbons is transferred to the medium (self-adhesive labels, wristbands, plastic cards, etc.) by heating.

Thermal transfer printing technology is also used to print textiles and they are also capable of direct thermal printing, so there is no need to use any ink ribbons.

Thermal transfer printing is also used by manual label makers, so the finished printed labels are long-lasting and very resistant to environmental influences.

TIP: "Card printing - how to choose the right ink ribbon?"

Fortunately, we have many variants of label printers and label makers to choose from, not only by printing technology, but also by resolution, print speed and print width, so you can choose the right one for you. You'll also appreciate the large selection of compatible self-adhesive thermal labels (DT) and compatible labels for TT in rolls, so you can save money and still not lose the quality of your printed labels.

Sára from CDRmarket