Tube markers: An essential tool for marking wires and cables

You've probably heard of machines that can print shrink tubes, plastic sleeves and other insulating materials that can easily mark any cable or wire. These machines are called tube printers or also tube markers. Both names are correct. But how do such tube markers or tube printers work and what are their advantages?

Tube printers

The most common markers are found, for example, in the wiring industry (marking of wires in switchboards, industrial installations and automation), the automotive industry (identification of cable harnesses and components), the telecommunications industry (marking of network and fibre optic cables) and also in the railway and aviation industry (precise and durable marking of wires).

How do they work?

The most common technology used by tube printers is thermal transfer printing. Thermal transfer printing takes advantage of the color ribbon, which is first heated in the printer and then transfers the dye to the surface of the shrink tubes or to the surface of the plastic sleeves. The result is a durable, long-lasting print that does not smudge and resists the elements.

The printing process takes place in several subsequent steps:

- Insertion of shrink tubes - Shrink tubes or regular tubes are inserted into the printer

- Settings of parameters - The user sets text, font size, possibly barcodes or graphic symbols

- Thermal transfer printing - The print head heats the color ribbon (thermal transfer film) and transfers the color to the surface of the tape or tube

- Cutting the tube - Some printers have an automatic cutter that immediately separates the shrink tube

- Use on wire or cable - The shrink tube is then placed on the cable (the shrink tube can also uses heat for a tighter fit)

Less commonly, laser or inkjet printing technology may also be used in tube markers. However, inkjet printing is the least used for tube printers due to the lower durability of the prints.

Consumables

Tube printers work with different types of insulation materials that vary in their durability, flexibility and suitability for specific applications.

The most commonly used tubes by material:

1. PVC tubes (Polyvinyl chloride)

- Low cost option, suitable for less demanding applications

- Resistant to moisture and mechanical damage

2. Shrink tubes (Polyolefin, PTFE, FEP, etc.)

- Most commonly used for professional marking

- After heating, they shrink to a smaller diameter and fix firmly on the wire or cable

- Excellent mechanical and chemical resistance, long service life

- Different shrinkage ratios (2:1, 3:1, 4:1)

3. Halogen-free tubes

- They do not contain halogens (e.g. chlorine or fluorine), so they do not emit toxic gases when burning

- Best suited for use in the rail, aerospace and automotive industries

- Meet strict safety standards

4. Teflon (PTFE) and silicone tubes

- Extreme temperature resistance (-200 °C to +260 °C), resistant to oils, solvents and acids

- They are used in the aerospace or medical industry

When choosing, it is important to check compatibility with the printer, especially in terms of diameter, thickness and type of surface of the shrink tubes. However, most tube markers can also print self-adhesive tapes, giving users more options for marking in their field.

Which brands and models of eyeliner printers can you find here?

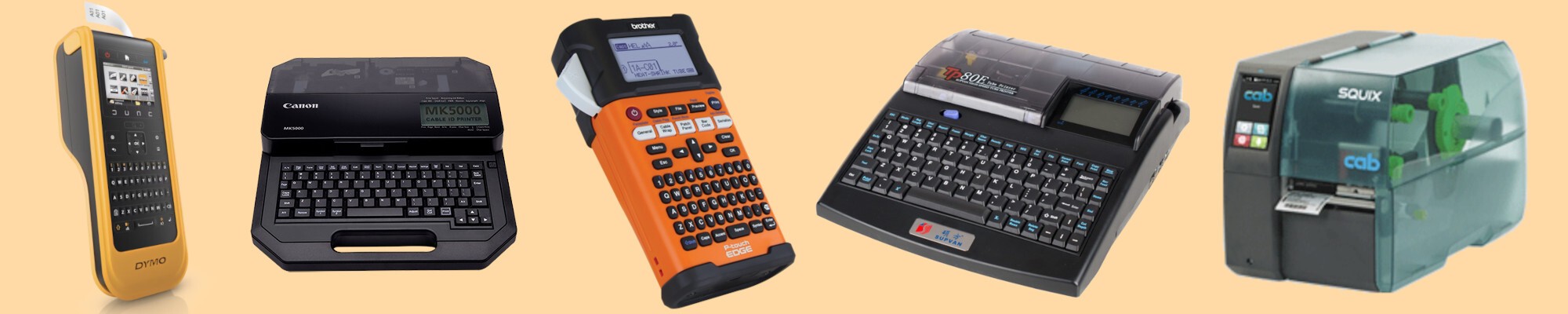

There are several reputable manufacturers of tube markers on the market, offering a variety of models from basic manual printers to fully automated industrial systems.

In our portfolio you will find tube printers from various manufacturers such as Biovin, Canon, L-Mark, MAX, Partex, PONY and Supvan, who specialize in the production of professional tube markers. But even manufacturers like Brother, Dymo, Epson, Brady and PONY offer shrink tubes in cartridges that can be used in some of their handheld and desktop label makers.

How to choose the right model for you?

If you're wondering what tube marker you should choose, ask yourself these important questions first:

1. What type of tube printer do I need? - Manual? Desktop? Or an industrial one?

2. What materials do I need to print on? - PVC tubes / Shrink tubes (polyolefin) / Halogen-free and special tubes (Recommendation.)

3. What features should the printer have? - Print resolution, print speed, connectivity options or software compatibility.

4. What are the printing costs? - Price of the printer, price of consumables, long-term availability of materials.

If you are still unsure about choosing the right tube printer after reading this article, please do not hesitate to contact us. We will be happy to advise you and recommend the best solution for your needs.

Sara CDRmarket